Description of work

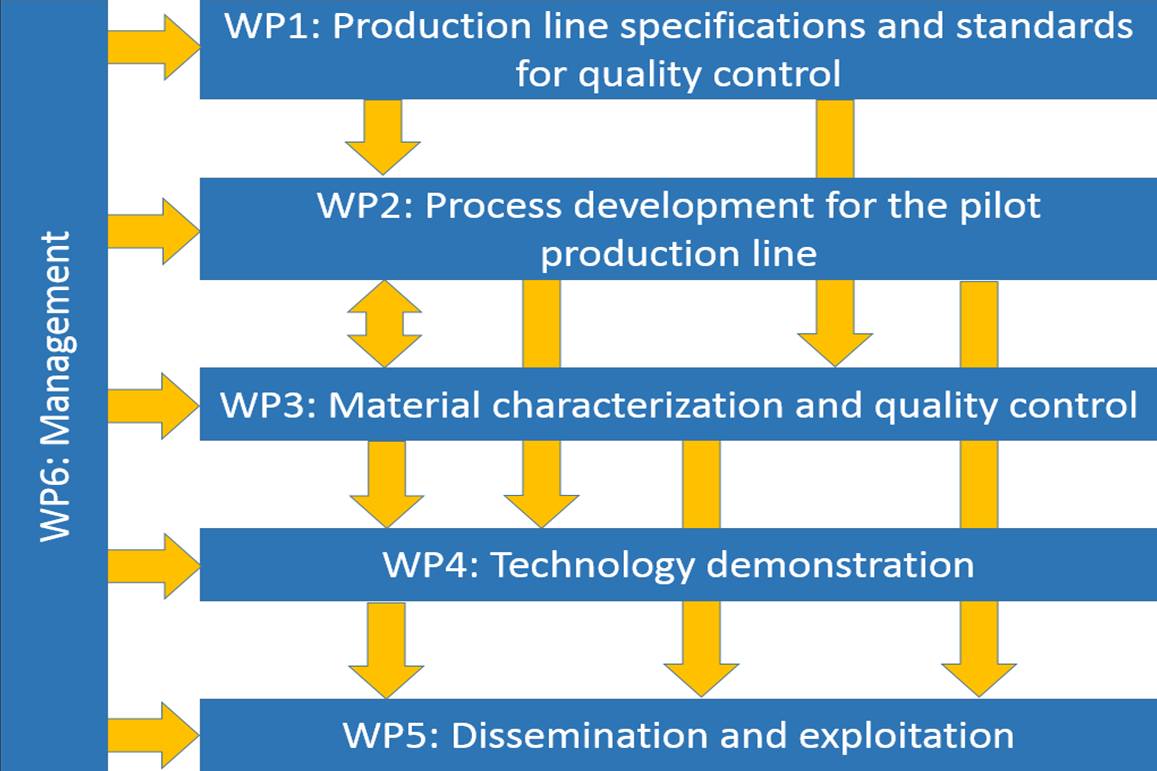

Figure above shows the overall structure of the work plan in SMARTHERM project. WP1 will define the specifications for the production line and the standards for the quality control of the CNT based TIM material. The purpose is to define the project production line in terms of production throughput requirement, material selection, performance, automation requirements and parameters for process control. Based on the specification and design on WP1, WP2 will develop and construct a roll-to-roll based high volume pilot production line with high degree of automation for the CNT based TIM. In WP3, the key parameters of the produced material that can be used for quality control during ordinary production will be identified. Structural, thermal, mechanical and interfacial properties of the produced TIM will be evaluated by various advanced experimental techniques and give the feedback to WP2. WP4 will apply the TIM produced in WP2 and integrate it into the avionics demonstrator to demonstrate its performance. WP5 will take care of the dissemination and business exploitation of the new TIM and WP6 is responsible for the general management in the project.